Colouring, characteristics and manufacture

Boiled (natural brown)

The willow harvest of our standard articles is cooked with bark for several hours.

During the long cooking process, the tannic acid in the bark is released and colours the white willow wood into the typical brown tone (a preservative effect also occurs). Subsequently, the willow is peeled.

The willow wood is then rinsed with clear water and, after complete drying, dipped in a colourless water-based varnish suitable for food. The basket surface is now protected by a protective film which prevents the penetration of dirt or germs.

White

The willow rods are peeled, i.e. the bark is removed. Afterwards the cooking process takes place. The now unpigmented (light) rods are interlaced directly in wet condition.

After completion, the rods are rinsed with clear water. As soon as the drying is finished, they are dipped in a water-based varnish suitable for food.

The delivery time for this execution usually lasts approx. 3 weeks.

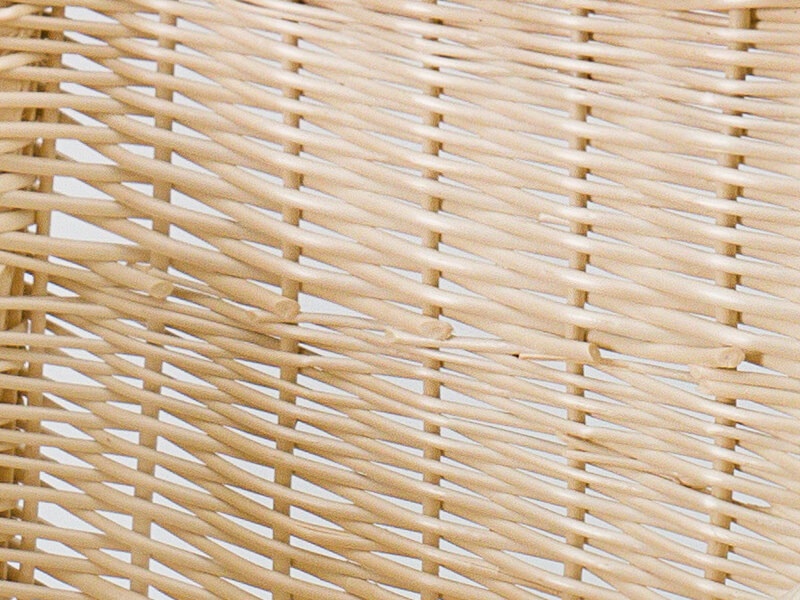

Bark

The willow rods are directly processed unpeeled without further pre-treatment. Their moisture content is relatively high and they are initially firmly interwoven.

After complete drying, the diameter of the willow rods shrinks slightly. This makes the entire wickerwork structure somewhat looser. Finally, the wickerwork is dipped in water-based varnish.

The delivery time for this execution usually lasts approx. 3 weeks.